Designed for both industrial-scale production and research laboratories, the high temperature furnace provides precise thermal processing capabilities for metal sintering, heat treatment, and advanced material development.

The high temperature furnace is widely used in universities, research institutes, and industrial facilities across sectors such as powder metallurgy, electronics, ceramics, pharmaceuticals, glass, sulfur materials, and chemical processing. This furnace is ideal for experimental setups and full-scale manufacturing that demand consistent performance, controlled atmospheres, and stable high-temperature operation.

| Model | 1200℃ | 1400℃ | 1600℃ | 1700℃ | 1800℃ |

| Max. working temperature | 1250℃ | 1450℃ | 1650℃ | 1730℃ | 1820℃ |

| Recommended working temperature | 1200℃ | 1400℃ | 1600℃ | 1700℃ | 1800℃ |

| Temperature accuracy | ±1℃ | ±1℃ | ±1℃ | ±1℃ | ±1℃ |

| Temperature control uniformity inside furnace | ±1°C (depending on the size of the heating chamber); multi-point temperature control can be implemented when higher precision is required |

||||

| Thermocouple and measuring range | Nickel-chromium-nickel-silicon(K) Measuring range: 0-1350°C |

Platinum-rhodium(S) Measuring range: 0-1700°C |

Platinum-rhodium(B) Measuring range: 0-1820°C |

Platinum-rhodium(B) Measuring range: 0-1820°C |

Platinum-rhodium or fiber optic infrared temperature measurement |

| Programmable segments | 1 group 50 segments; 2 group 22 segments; 3 group 8 segments | ||||

| Heating rate | 1℃/h to 40℃/min adjustable | ||||

| Heating element | Silicon carbide rod | Silicon carbide rod | 1800 silicon molybdenum rod | 1800 silicon molybdenum rod | 1900 silicon molybdenum rod |

| Heating element installation | Installed vertically in two sides of the furnace | ||||

| Refractory materials | High purity alumina fiberboard | High purity alumina fiberboard | Imported high purity alumina fiberboard | Imported Morgan lightweight materials | Imported high purity Morgan lightweight materials |

| Cooling structure | Double layer furnace shell, air cooling | ||||

| Furnace temperature | ≤45℃ | ≤45℃ | ≤45℃ | ≤45℃ | ≤45℃ |

| Communication port | RS485 RS232 USB | ||||

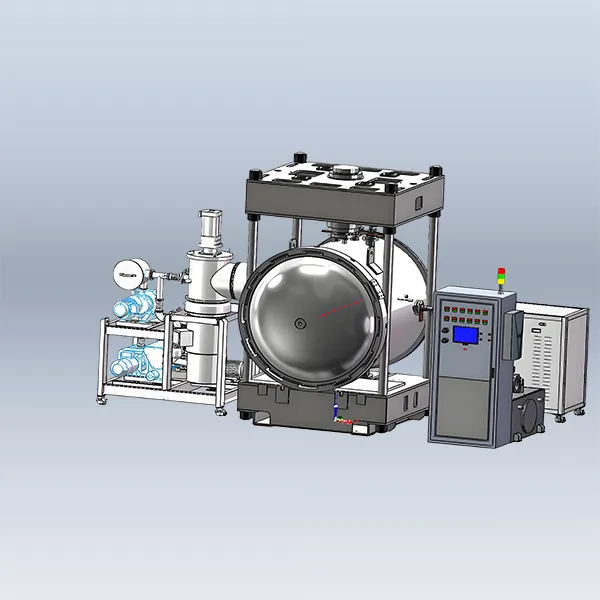

Our high temperature furnace is engineered to deliver precise and clean thermal processing, especially for applications where oxidation, decarburization, and part distortion must be minimized. The system supports vacuum heating, as well as normal or high-pressure gas quenching, depending on process requirements. A key factor in modern heat treatment quality is the uniformity of gas flow during quenching, which directly affects the hardening performance and consistency of the treated parts. This uniformity is a hallmark of advanced thermal processing technology and is critical for achieving tight tolerances and repeatable results in both research and industrial production settings.

Complete turnkey solutions for forming equipment and production lines